Cutting Edge Design and Precision Engineering

How cutting edge geometry ensures clean wire separation

Blade shape really matters for how well it cuts wires. When blades are ground at angles between about 55 to 65 degrees, they create just the right kind of cutting force that goes through conductors while leaving the insulation intact. This makes all the difference when dealing with delicate copper network cables or automotive wiring where damage isn't an option. The newer micro-bevel designs, which are only around 0.1 to 0.3 millimeters wide, focus the cutting action on a much smaller area. According to some recent testing from last year, these specialized edges cut down on fraying by roughly three quarters compared to older flat edge designs. Shop owners who have switched over report noticeable improvements in their work quality.

Diagonal, round, and flush cutter edge types compared

- Diagonal cuters: Angled blades (15–30°) are ideal for cutting piano wires and hardened steel cables up to 5mm diameter

- Round-nose cutters: Curved edges prevent slippage when trimming zip ties in tight electrical panels

- Flush cutters: One flat-ground side enables cuts flush with surfaces, leaving 0.2mm protrusion–crucial for jewelry and precision fabrication

Beveled vs. flat edges: Performance in precision tasks

Beveled edges require 34% less hand pressure than flat designs, according to ergonomic studies, thanks to their tapered profile (0.5–2mm slope). This allows precise contact placement for delicate operations such as severing 36 AWG magnet wire without damaging nearby components or trimming 3D-printed polymer prototypes with 0.05mm accuracy.

High-frequency quenching and its role in edge retention

Today's wire cutters typically go through a process where they apply heat specifically to certain areas using induction methods around 800 to 850 degrees Celsius before cooling them down quickly in oil. This makes the actual cutting parts really tough, reaching hardness levels between 58 and 62 on the Rockwell scale, while keeping the handles at about 45 HRC so they can absorb some impact when cutting. The difference this makes is pretty significant actually. Tests lasting over 300 hours showed these specially treated cutters lasted roughly four times longer than regular ones when making continuous cuts on 2mm stainless steel wire. That kind of durability matters a lot for professionals who need reliable tools day after day.

Blade Material and Hardness: The Role of High HRC Steel

Selecting the right blade material determines whether cutters cleanly slice or crush wires. The optimal blend of steel composition and hardness ensures durability across thousands of cuts while resisting corrosion and deformation.

Why Chrome Vanadium Steel Excels in Durability and Corrosion Resistance

Chrome vanadium steel contains 10–13% chromium, which forms a protective oxide layer that resists rust in humid environments. Its vanadium carbides enhance wear resistance, enabling it to maintain structural integrity when cutting wires up to 60 HRC–outperforming stainless steel by 15% in deformation resistance.

Understanding HRC Ratings and Their Impact on Cutting Performance

Blades rated 58–62 HRC strike the best balance between hardness and toughness–rigid enough to cleanly shear copper strands yet resilient enough to resist chipping. Blades below 55 HRC deform when cutting steel cables, while those above 64 HRC become brittle and prone to edge fractures.

Heat Treatment Techniques for Long-Lasting Blade Hardness

A multi-stage process involving austenitizing at 815°C (1,500°F), oil quenching, and tempering at 205°C stabilizes the steel’s microstructure. This eliminates internal stresses that lead to micro-fractures, increasing blade lifespan by 40% compared to untreated steel.

Jaw Shape and Access: Tapered, Oval, and Flush Designs

Tapered Jaws for Improved Access in Tight Spaces

Tapered jaws have this narrow shape that makes them really useful for getting into tight spots where regular tools just won't fit. Think about working on electronics inside a computer case, HVAC ductwork, or those tricky places in car engines. Most of these specialized cutters come with angles ranging from around 15 to 30 degrees, which lets technicians cut wires right next to sensitive circuit boards or behind panels without messing up anything else nearby. Another great thing about this design is how it actually helps see what you're doing when making those angled cuts, so there's less chance of accidentally nicking something important while working in cramped conditions.

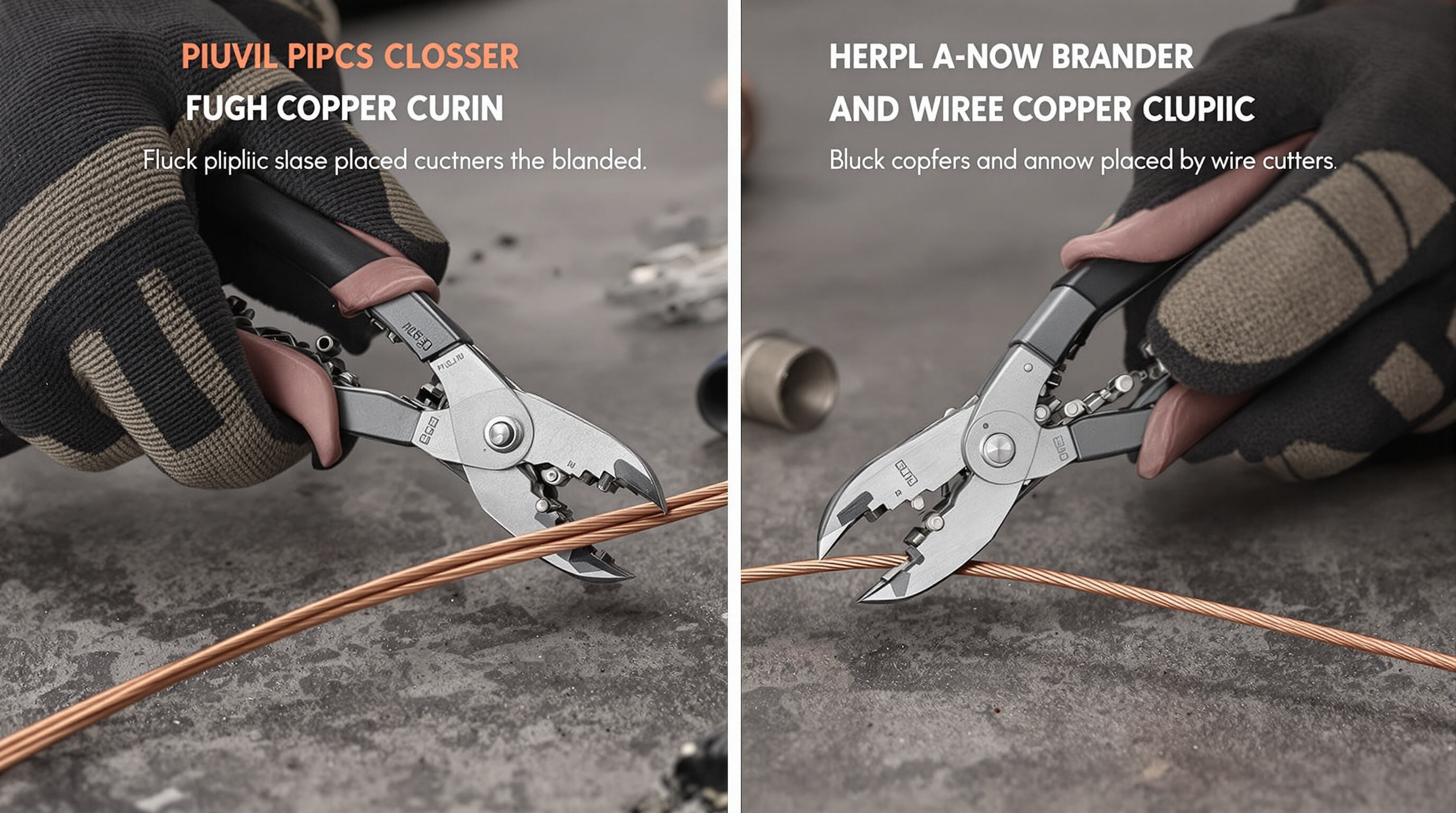

Oval vs. Flush Jaw Designs: Reducing Burrs in Delicate Applications

Oval jaws are pretty versatile for sure, but when it comes to getting those clean, burr free cuts, nothing beats the flush jaw setup. These jaws line up the edges just right when they close down on the material. The result? Much less metal distortion especially noticeable when working with softer stuff like copper or aluminum sheets. According to industry research, using flush jaws can cut down on extra finishing work anywhere from 40% all the way up to 70%. That makes these tools practically indispensable in high precision fields such as aircraft wiring installations and the production of medical devices where even tiny imperfections just won't do.

Case Study: Why Jewelry Makers Prefer Flush-Cut Precision

For those working with fine metals like gold and silver, flush cut wire cutters are practically indispensable in jewelry making circles. The design with no gap between blades creates clean cuts that make soldering much easier while keeping delicate gemstones safe from scratches during the process. When we looked at data from around 200 independent jewelry studios last year, most reported noticeable improvements in quality control after making the switch to these specialized cutting tools. About 8 out of 10 shops saw a drop in defective pieces, which explains why so many serious craftsmen now consider flush cutters essential equipment for precision work.

Side-Cutting vs. End-Cutting Functionality in Real-World Use

Side-cutting cutters provide lateral access, allowing electricians to trim wires flush against junction boxes or conduit. End-cutting models, with forward-facing blades, offer superior control for removing protruding wire ends in upholstery and marine rigging. Professionals often carry both–side-cutters for fast bundling and end-cutters for detailed finishing.

Matching Cutting Capacity to Wire Gauge (AWG) Requirements

Aligning Cutter Capacity with AWG Standards for Electrical and Industrial Wires

Clean cuts depend on matching the cutter’s capacity to the wire’s American Wire Gauge (AWG). This standardized system defines diameters and current ratings for safe, efficient cutting. For example:

| AWG | Diameter (mm) | Common Applications |

|---|---|---|

| 18 | 1.02 | Thermostats, low-voltage lighting |

| 14 | 1.63 | Household lighting circuits |

| 10 | 2.59 | Dryers, 30-amp outlets |

| 4 | 5.19 | Industrial heaters, EV chargers |

Exceeding a cutter’s rated capacity risks blade deformation or incomplete cuts. Industrial wires (4 AWG) demand hardened steel jaws, while thin electronic wires (18–24 AWG) require precision-ground edges to prevent fraying.

Maximum Gauge Limits Across Needle Nose, Diagonal, and Linemen’s Cutters

Cutting capacity varies significantly by tool type:

| Cutter Type | Max Recommended Gauge | Typical Use Case |

|---|---|---|

| Needle Nose | 14 AWG | Electronics, tight-space repairs |

| Diagonal | 10 AWG | HVAC, automotive wiring |

| Linemen’s | 6 AWG | Electrical panels, thick cables |

Linemen’s cutters use compound pivot mechanics to cut 6 AWG copper (5.2mm) with 30% less hand force than standard models. Always adhere to the manufacturer’s AWG rating to avoid tool damage and ensure safe terminations.

Leverage, Pivot Mechanics, and User Efficiency

How pivot placement influences cutting force and reduces user fatigue

When tools have their pivots placed strategically, they actually give users a better mechanical advantage. Studies from the Ergonomic Tool Institute back this up, showing hand force requirements drop somewhere between 40 to maybe even 60 percent compared to regular tool designs. Moving that pivot point just a little bit closer to where the actual cutting happens makes all the difference. We're talking about something like shifting it 2 millimeters toward the blade edge, which according to basic lever principles cuts down on the effort needed by around 28%. For electricians working with thick copper wires, this matters a lot. They can slice through 12 AWG copper with roughly 22% less gripping pressure than before. Less strain on hands means fewer chances of developing those annoying repetitive strain injuries that plague so many tradespeople over time.

Evaluating leverage ratios in professional-grade wire cutters

Top quality tools come with leverage ratios ranging between 3:1 and 5:1, finding that sweet spot where power meets practicality. Take the 4:1 ratio model for instance it can slice through 10 gauge steel wire using just 15 pounds of pressure, way better than the 23 pounds needed by those basic 2.5:1 versions on store shelves. Plus, these premium models keep things manageable with a 6.3 inch handle length that fits nicely in most workshops. Now when we get into ratios over 5:1, they're fantastic for cutting thick industrial cables but there's a catch. The handles need to be about 38 percent wider which makes them awkward to maneuver in cramped areas where precision matters most. Most professionals find this tradeoff worth it for heavy duty jobs though.

FAQs

What is the significance of beveled edges in wire cutters?

Beveled edges require less hand pressure and enable precise contact placement, making them ideal for delicate operations like severing thin magnet wire or trimming 3D-printed prototypes.

Why is Chrome Vanadium Steel preferred for wire cutters?

Chrome Vanadium Steel resists rust and maintains structural integrity under stress, making it durable and ideal for heavy-duty cutting tasks.

How do leverage ratios affect the usability of wire cutters?

Higher leverage ratios reduce hand force requirements, making wire cutters more efficient and reducing user fatigue, which is especially beneficial in professional settings.

What is the advantage of flush jaw designs?

Flush jaw designs offer clean, burr-free cuts, significantly reducing the need for extra finishing work, crucial in precision fields like aircraft wiring and jewelry making.